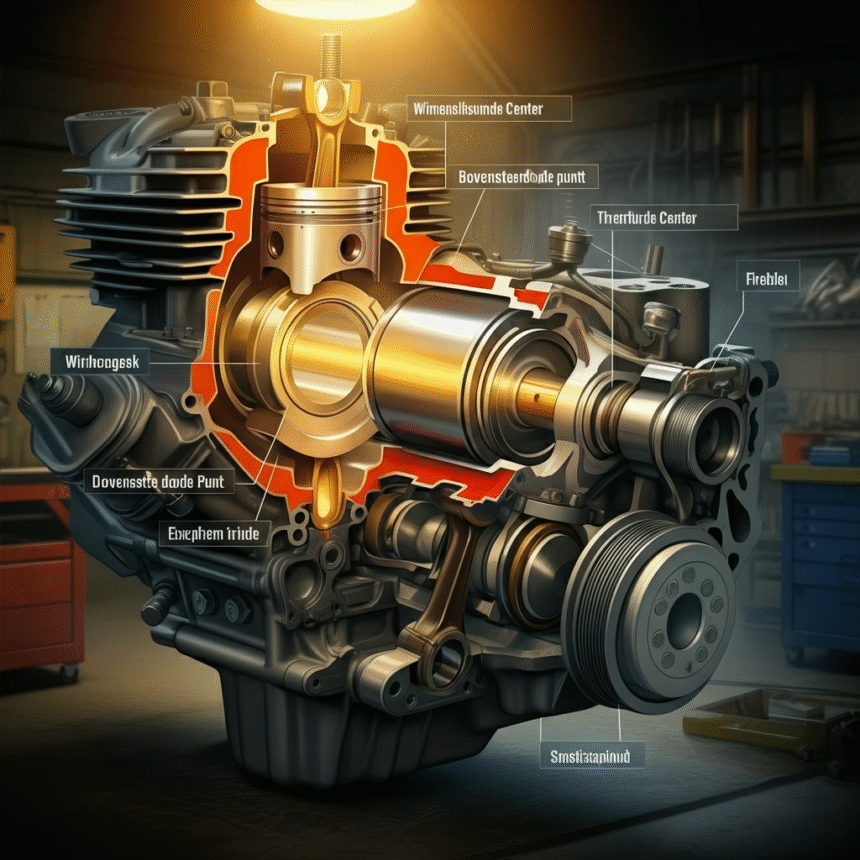

Engines are intricate systems, but at the nucleus, there is a notion referred to as “Top Down Center“ or Top Bovenste Dode Punt (TDC). If you are an automotive aficionado wishing to learn the mechanistic side of things, be it a longstanding mechanic, knowing TDC is important. This post will discuss the definition of TDC and its significance concerning engine timing and power performance, its accurate identification methods, and the possible implications of incorrect TDC settings.

So, What Is Top Bovenste Dode punt Center and Why Is It Important?

Top Bovenste Dode punt Center (TDC) is the element described as the advanced point in fuel piston cycle where its highest peak in the cylinder is achieved. Although a vehicle has an array of fuel pistons, the way each one having its own TDC will result in understanding the ‘state of being’ as well as the harmony of internal combustion process on device.

With the proper functioning of the engine being highly dependent on TDC, while recognizing that TDC denotes one of the moments where the blendessential to the TBZ- fuel, air, and spark together produce the force highly essential to power the vehicle enables an engineer to understand better why the setting of TC calibrates everything from ignition timing to valve movement while determining efficiency and performance renders TDC considerable.

For those who are aware of the workings of a four-stroke internal combustion engine, you know there are four processes in a cycle:

Intake stroke: The piston goes downward, bringing in the fuel and air mixture into the cylinder.

Compression stroke: The piston rises again, and the mixture is compressed.

Power stroke: The mixture is set on fire with spark ignition when it is near TDC, and it forces the piston downwards.

Exhaust stroke: The piston goes further upwards and removes the burnt gases from the piston.

TDC takes place when the piston is at the highest vertical position in the cylinder at the end of the exhaust stroke, and during the compression stroke. Nevertheless, TDC during compression stroke is most important because of the critical role ignition timing has in optimizing power.

How TDC Affects Performance and Timing of the Engine

Correct allocation of TDC guarantees that the pump will have the right sequence of timing for spark ignition, valve, and cylinder head rotation. If the spark is delivered either too early and too late in relation to TDC, it may cause catastrophic consequences concerning performance as well as mechanically. Let’s analyze:

1. Timing of the Ignition

For the modern engines, TDC marks the start of the most critical phase of the cycle – timing of the ignition. This is where the engine needs an explosion of power. The sophisticated internal combustion engines are equipped with ‘advanced timing,’ where the spark plug fires just prior of TDC during the compression stroke.

Why This Matters: Incorrect timing could lead to “knocking” or “pinging,” which can damage engine components or reduce efficiency.

2. Valve Timing:

The Control of the Internal Combustion Engine has to deal with the opening and closing of the induction and exhaust valves which move in accordance with the piston’s position. The starting point is TDC which also acts as the zero point of the interval where the valves are supposed to actuate.

Why This Matters: Mistimed valves can cause a loss of power, incomplete fuel combustion, and an increase emissions.

3. Compression Pressure

The amount of internal pressure contained within the engine subsystems also has a strong correlation with TDC.

Correct performance hinges on optimal compression which means that the piston must be at TDC in order to create the necessary pressure for the fuel to combust.

Steps to correctly ascertain TDC

Setting TDC correctly is essential and most mechanics use the following methods to ensure it is spot on:

1. The Bump Stop Method

This manual method consists of putting a stopper into the spark plug hole to lightly block the piston’s movement. TDC is then determined as the marker in between the two mark positions after turning the crankshaft in any direction.

2. Dial Indicators

Dial indicators are accurate devices for determining TDC because of the measurement precision they provide. This tool is affixed to the cylinder head and it quantifies the movement of the piston in the cylinder. The reversal point of the dial represents the TDC position.

3. Timing Indicators on Harmonic Balancer or Crankshaft Pulley

Most engines come equipped with TDC timing marks located on the crankshaft pulley or harmonic balancer which are pointed and aligned by a pointer fixed on the engine block.

4. Measurement of Cylinder Pressure

With pressure gauges connected to the cylinder, mechanics can easily know the point at where the piston alternates with air compressing it to the maximum pressure TDC indicating the compression stroke.

Tip: Make sure you are not identifying TDC on the exhaust stroke otherwise timing would be set wrongly.

Problems Resulting from Improper Configuration of TDC

Not setting or identifying TDC accurately can lead to a variety of issues shown below along with their impacts.

Engine Timing Errors

Incorrect setting of TDC will result in al combustion cycles being disrupted leading to an misfire of the engine, power failure, and even increased dependancy on fuel.

Severe Combustion Engine Damage

Incorrect TDC timing setting causes gist pre-ignition or knocking. These may cause internal components of the engine to get bad damaged.

Mechanical System Failure

With increased risk of operating valves out of their schedule leads a greater prospect for the valves hitting the pistons resulting in sudden destructive mechanical critcal failure.

Farmers utilize a range of techniques and offer suggestions that develop an optimal fuel consumption per hour.

Utilization of GPRS, GPS & Networked Computers

These technologies are essential for optimum placement of machinery over fields helping to minimize travel costs and idle time. These also helps in scheduling preventive maintenance. Out of the above tools, the GPS is beneficial for delineating areas with differing terrain and topography as well as contour plowing.

Utilization of Hybrids & Machines

Combining farms with livestock further distinguishes idle time. This enhances the output. Changes in hybrid placement further modify outputs. Adopting new livestock hybrids as well as specializing in Santa Gertrudis and Santa Cruz cattle varieties marks a major change.

Some farmers seek economic aid for constructing barns, and offer subsidies used for the disabled in place of cattle barn rented through the as enhancement on the economic level.